As a global manufacturer of Coiled Tubing Pressure Control Equipment, including Blowout Preventers, Rotating Joints, Lubricators, we focus on creating products that meet your needs regarding efficiency and safety.

With NXL as your manufacturing partner, your company will have the peace of mind that you are utilizing superior equipment, professional solution-based knowledge, fast delivery times, and well-stocked spare parts to keep your operation running efficiently. In addition, our engineering team can customize many of our equipment models to suit your needs.

Blowout Preventers

NXL Technologies offers a complete line of Pressure Control Blowout Preventers (BOPs). Our BOPs come in a variety of styles, sizes, and pressure ratings. Find out more about our Blowout Preventers.

Stripper Packers

NXL has Pressure Control Stripper Packers available with a range of internal diameters and working pressures up to 15,000 psi. Find out more about our Stripper Packers and accompanying PCE equipment.

Crossovers

NXL provides Pressure Control Crossovers in all sizes and pressure ranges. Our Crossovers can be configured to your equipment needs.

Flanged Adapters / Swedges

If your oil & gas operation requires Pressure Control Flanged Adapters, NXL has you covered. We manufacture Flanged Adapters or Swedges in all sizes and pressure ranges. As well, our Adapters or Swedges can be configured to your equipment needs.

Flanged Spool Adapters

NXL manufactures Pressure Control Flanged Spool Adapters in all sizes and pressure ranges to meet the needs of your operation. And to meet your equipment needs, our Spools can be customized. Find out more here.

Flow Tees & Flow Crosses

NXL provides Pressure Control Flow Tees, and Flow Crosses with adaptable ports. Our Flow Tees and Flow Crosses can be configured to specific bore sizes and end connections, and different working pressures ranges are available.

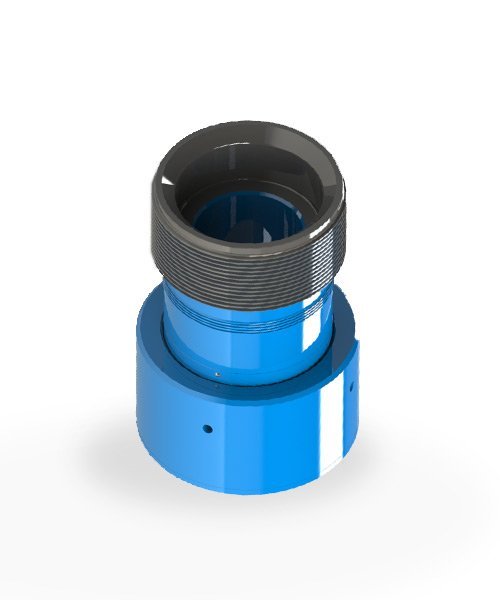

Hydraulic Quick Latch

The NXL Hydraulic Quick Latch improves efficiency and safety while reducing rig-in time by providing a remote locking well connection system. Find out more about our PCE.

Injection Subs

NXL Technologies supports your coiled tubing operation with our innovative injection subs. Like our other PCE, our injection subs can be customized to meet the unique needs of your team.

Lubricators

Pressure Control Lubricators or Risers are available with internal diameters from 2-9/16” to 7”, working pressures up to 15,000 psi, and a variety of customizable lengths through NXL Technologies.

Night Caps & Lifting Caps

NXL designs and manufactures a wide range of Pressure Control Equipment Night Caps and Lifting Caps to fit and lift your Pressure Control Equipment. Explore our Night & Lifting Cap options.

Quick Test Subs

Pressure Control Quick Test Subs with multiple connection options can better fit your operation's needs. The Quick Test Sub from NXL provides an additional element of safety along with being more efficient. Find out more here.

Rotating Joints

With our innovative Rotating Joint designs, NXL has developed an equipment line that allows for easier connections and transfer of power and pressure. Explore our Rotating Joint options.